Jordan Letchford

Mechatronics Engineer with minors in Software and Robotics

I am an innovative Mechatronics Engineer with a passion for design, manufacturing and being on the leading edge of technology. I have developed a high level of knowledge with 10 years of experience in 3D modeling and 3D printing. My last two years have been focused on delivering R&D solutions for industry problems, where I have worked acrosss a vast number of engineering fields. These experiences have laid the foundations for strong problem-solving abilities and maintaining a high standard of quality. I strive in a highly communicative environment and uphold a strong desire to take every opportunity to expand my skills and grow as a professional engineer.

Technical Skills

A representation of my proficiency in each skill

Fusion360

This platform is my go-to design software, as it encompasses powerful tools for mesh editing, designing, rendering, CAM and simulations.

3D printing

Performed professionally and as a hobby for years. I have utilised machines from company's such as Stratasys, Prusa, Anycubic and Creality which entail FDM, SLA and Polyjet.

Microsoft Office/Overleaf/Python

Used professionally throughout various industries.

Visual Components/Thingsboard/Github

Visual Components is a software that enables advance factory automation simulation. Thingsboard is a IOT software, that allows remote monitoring and data analysis of products from anywhere in the world.

C++/C/Matlab/HTML

Used lightly professionally and throughout my university degree to perform various projects in MicroControllers, web building and data analysis.

Solidworks/Codesys(PLC)

Codesys is a PLC programming software that allows for specific PLC's to be programmed in structure text and or ladder logic. Throughout various projects, I have lightly utilised Solidworks.

Professional Skills

Problem-Solving

I enjoy taking on problems and formulating a solution, which is evident in all of my projects.

Teamwork/Individual work

I strive in a collaborative environment where ideas can be bounced around however am not afraid to tackle problems solo.

Leadership/Project Management

I am happy to step out of my comfort zone and manage, direct and or resolve team issues while ensuring the project progresses effectively and efficiently .

Self-Driven

I am a highly motivated individual who can be relied upon to perform tasks to a high standard without the need for follow up.

Client and Result Orientated

I go above and beyond to ensure tasks are completed at a high standard and always aim for client satisfaction.

Proactive

There is no better time to start something, than right now. Work does not complete itself.

One-Shot 3D-Printed Multimaterial Soft Robotic Jamming Grippers

I was given the task to create a "dog paw" inspired robot foot that was not in existance. The design of the foot was required to handle various terrains and be able to pick up objects through jamming. The results of this work were published to lay the foundations for further research into this concept.

- Published in Soft Robotics -

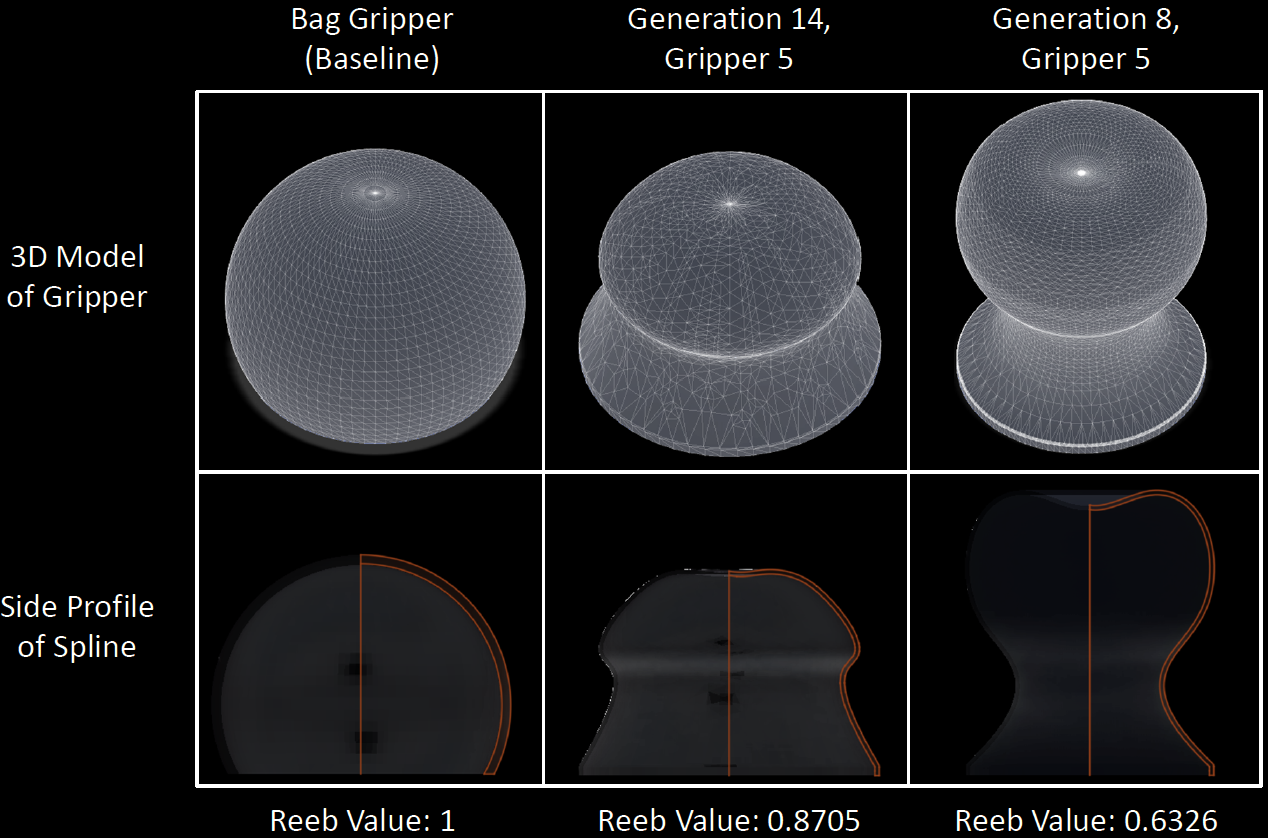

Getting a Grip: in Materio Evolution of Membrane Morphology for Soft Robotic Jamming Grippers

By exploring the geometry of soft gripper, the shape of a gripper can be refined to produce the optimal performance required for a particular object.

- Archived at arXiv.org -

Smart Farming - Advance Agriculture Technology

We're helping Australia take giant leaps in Agricultural innovation by advancing how medication is administered to cows. Packaged into a small box, this technology determines which animal it is and automatically applies the right medicine in the correct dosage.

- Presented on Linkedin -

Australian made reverse vending machine using AI technology for the "Container for Change" initiative

To assist Australia in the "Container for Change" initiative, I was part of the team that created an Australian-made, AI smart machine that could collect, sort and pay the public to return empty bottles.

All-terrain "dog inspired" robotic leg with jamming capabilities

I was given the task to create a "dog paw" inspired robot foot that did not exist, it had to handle various terrains and be able to pick up objects through jamming. This is the solution I derived.

Human interactive Robotic Incremental Sheet Forming process

To assist with introducing Robotic Incremental Sheet Forming into the art and design industry, a human interactive process was developed to accelerate and enable the manufacturing process to be more user friendly and adoptable into a new industry.

Face shields for health care workers

During the COVID19 pandemic, face shields were in high demand for our front line workers.

Assisted and redesigned a working replica of the Spot Mini

With a strong passion in robotics, I assisted in improving, designing and making more easily available a working replica of the Boston Dynamics Spot Mini dog.

Development of a robotic gripper for aerial manipulation to assist with carrying payloads on drones

I was tasked to create a gripper with a time of flight sensor, that could assist in carrying objects on a drone.

A Real life size, interactive Millennium Falcon cockpit for Disney

I designed the intricate parts of the cockpit based off of the movies and manufactured them through 3D printing. This project is now on display at David Jones in Sydney.

Demonstration model of Hierarchical Optimization to produce robotic evolution

I designed a model for interactive display purposes of a research topic performed by Joshua Pinskier.

Demonstration model of the wheeled rover with posable hubs

I designed a model for display purposes of a research topic performed by Tim Hojnik.

University related projects

I carried out projects that involved robotics, design, fabrication, programming, vision, SLAM, autonomy, embedded systems and sensors.